Guide

How to Make Limestone Pellet and Extruder Machine for Sale in Pakistan: Advanced Fertilizer Production Solutions

Published

3 days agoon

By

Admin

Agriculture is the backbone of global food security, and fertilizers play a crucial role in enhancing soil fertility and crop yield. Among the most commonly used fertilizers are limestone pellets and NPK compound fertilizers. Modern equipment such as the limestone powder granulation machine and the extruder machine for sale in Pakistan allows manufacturers to produce high-quality fertilizers efficiently, consistently, and at industrial scale.

This article will guide you through the process of making limestone pellets, highlight the benefits of extruder machines, and explain why these technologies are essential for modern fertilizer production.

How to Make Limestone Pellet: Efficient Soil Amendment

Why Use Limestone Pellets?

Limestone is widely used in agriculture to neutralize acidic soils, improve soil structure, and enhance nutrient absorption. While powdered limestone is effective, producing how to make limestone pellet offers multiple advantages: easier handling, reduced dust, uniform application, and better storage stability.

Limestone Pellet Production Process

- Raw Material Preparation

Limestone powder is crushed and screened to remove impurities and achieve uniform particle size. - Granulation

Using a limestone powder granulation machine, the powder is mixed with a binding agent or water and formed into uniform pellets. - Drying and Cooling

The pellets are dried to reduce moisture content and cooled to maintain hardness and stability. - Screening and Packaging

Finished pellets are screened for consistent size, with off-size pellets recycled into production. The final product is then packaged for storage or distribution.

Benefits of Limestone Pellets

- Uniform Application: Ensures even spread on fields, optimizing soil treatment.

- Reduced Dust and Waste: Granules minimize powder loss during handling and transportation.

- Enhanced Storage: Durable pellets resist caking, making storage and transport easier.

- Customizable Production: Pellet size can be tailored to specific agricultural requirements.

By transforming powdered limestone into pellets, manufacturers can improve product quality, efficiency, and profitability.

Extruder Machine for Sale in Pakistan: High-Quality NPK Fertilizer Production

What Is an Extruder Machine?

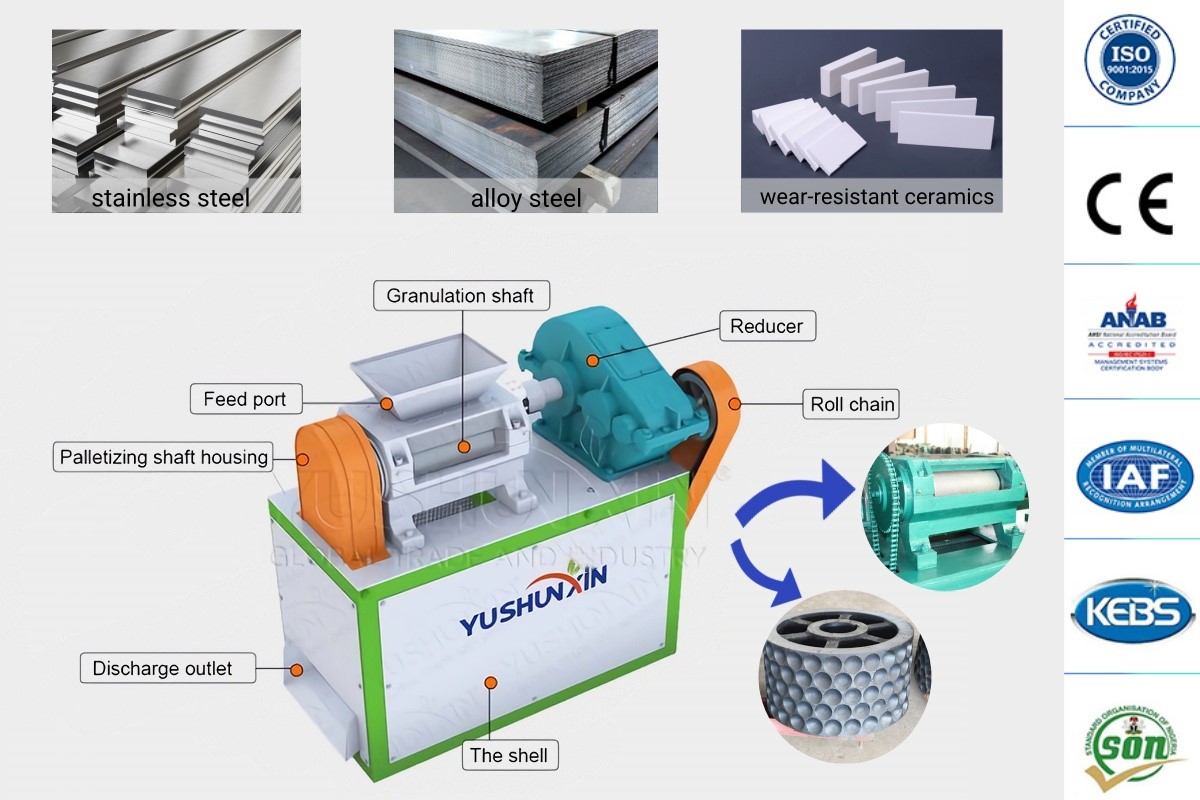

An extruder machine is a key piece of fertilizer manufacturing equipment designed to produce NPK (Nitrogen-Phosphorus-Potassium) compound fertilizers. NPK fertilizers are essential for providing balanced nutrients to crops, supporting root development, flowering, and fruiting. The extruder compresses blended powders into uniform granules, ensuring consistent nutrient distribution.

NPK Extrusion Process

- Raw Material Preparation

Fertilizer-grade urea, ammonium phosphate, potassium chloride, and other essential nutrients are crushed, screened, and blended. - Extrusion

The blended powder is fed into the extruder, which compresses it under high pressure to form dense, uniform granules. - Drying and Cooling

Granules are dried to reduce moisture and cooled to stabilize their structure. - Screening and Packaging

Granules are screened for uniform size, off-size particles are recycled, and the final product is packaged for sale.

Benefits of Extruder Machines

- High Production Efficiency: Continuous operation maximizes output and reduces production time.

- Uniform Granules: Every granule contains balanced nutrients for optimal crop growth.

- Customizable Fertilizer Formulations: Fertilizers can be tailored for specific crops or soil types.

- Cost-Effective Operation: Reduces raw material waste and energy consumption.

- Scalable Production: Suitable for small, medium, or industrial-scale operations.

Investing in an extruder machine for sale in Pakistan enables manufacturers to produce premium NPK fertilizers reliably and profitably.

Advantages of Modern Fertilizer Granulation Technology

1. Increased Production Efficiency

Modern granulation and extrusion systems allow continuous or semi-continuous production, producing large quantities of fertilizers with minimal downtime.

2. Consistent Product Quality

Controlled granulation ensures uniform granule size, density, and nutrient content, improving fertilizer performance and crop yield.

3. Reduced Operational Costs

Automation, energy-efficient designs, and recycling of off-size granules reduce labor and raw material costs, boosting overall profitability.

4. Versatility

These machines can process a variety of raw materials, including limestone powder, urea, ammonium phosphate, and potassium salts, enabling the production of a wide range of fertilizers.

5. Environmental Sustainability

Modern systems minimize dust, emissions, and waste, supporting eco-friendly operations and compliance with environmental regulations.

Applications in Agriculture

- Soil Neutralization: Limestone pellets improve soil pH and structure for better crop growth.

- Balanced Fertilization: NPK granules provide essential nutrients to cereals, fruits, vegetables, and horticultural crops.

- Custom Fertilizer Formulations: Machines allow production tailored to specific soil and crop needs.

- Export Opportunities: High-quality pellets and granules meet international standards, expanding market potential.

Producing consistent, high-quality granules and pellets ensures better agricultural results and higher profitability.

Choosing the Right Fertilizer Equipment

When selecting a limestone powder granulation machine or an extruder machine, consider:

- Production Capacity: Ensure the machine meets current and future production requirements.

- Raw Material Supply: Confirm steady availability of limestone, urea, ammonium phosphate, and potassium salts.

- Automation Level: Higher automation reduces labor costs and improves product consistency.

- Customization Options: Granule size, density, and nutrient ratio should be adjustable.

- Supplier Support: Choose a reputable supplier providing installation, training, maintenance, and spare parts.

Selecting high-quality equipment ensures efficient, safe, and profitable fertilizer production.

Conclusion

Modern equipment for how to make limestone pellets and extruder machine for sale in pakistan provides efficient, sustainable, and scalable solutions for fertilizer production. Limestone pellets improve soil quality and handling, while extruded NPK fertilizers supply balanced nutrients essential for optimal crop growth.

By adopting these technologies, manufacturers can increase production efficiency, reduce costs, maintain consistent product quality, and meet growing market demand. Investing in advanced fertilizer production equipment ensures long-term profitability, sustainable operations, and a competitive advantage in the agriculture industry.

Everything You Should Know About Opiniones-Plataforma-en-Espana.es

UK visa refusal: what it really means and how to respond the right way

How to Elevate Your Email Marketing Strategy

Best AliExpress Alternatives for Faster Shipping and Fewer Refunds

Carousel Manufacturer and Ferris Wheel for Sale: Top Amusement Park Rides

Large-Scale Continuous Furnaces and Charcoal Production Plant: Industrial Charcoal Manufacturing Solutions

How to Make Limestone Pellet and Extruder Machine for Sale in Pakistan: Advanced Fertilizer Production Solutions

Where Wild Dreams Walk Free: Deep Inside Tanzania Safari Life

Student Flats in Leicester: Studio or Shared – Which Is Better?

S.O.S. vs block bottom paper bags: design differences

Who Is Kate Garraway New Partner? The Truth Revealed

Brandi Raines Net Worth 2025: Age, Bio, Career, Husband and Children

Betsy Grunch Net Worth 2025: Salary, Career, Husband, and Life Story

Salma Shah Biography: Age, Career, Net Worth, Husband and Children

Nomia Iqbal Biography: Age, Husband, Career, Net Worth and BBC Journey

Kay Crewdson Biography: Age, Date Of Birth, Husband, Children, and Net Worth

Sophia Wenzler Biography: Age, Date of Birth, Husband, Career Story, and Net Worth

Ági Barsi’s Untold Story: Sister Of Judith Barsi And Her Battle With Cancer

Mike Danson Biography: Age, Net Worth, Wife, Children and Full Story

What Is eTarget Limited? The Truth Behind Those Mystery Parcels

Everything You Should Know About Opiniones-Plataforma-en-Espana.es

UK visa refusal: what it really means and how to respond the right way

How to Elevate Your Email Marketing Strategy

Best AliExpress Alternatives for Faster Shipping and Fewer Refunds

Carousel Manufacturer and Ferris Wheel for Sale: Top Amusement Park Rides

Large-Scale Continuous Furnaces and Charcoal Production Plant: Industrial Charcoal Manufacturing Solutions

How to Make Limestone Pellet and Extruder Machine for Sale in Pakistan: Advanced Fertilizer Production Solutions

Where Wild Dreams Walk Free: Deep Inside Tanzania Safari Life

Student Flats in Leicester: Studio or Shared – Which Is Better?

S.O.S. vs block bottom paper bags: design differences

Categories

Trending

-

News4 months ago

News4 months agoWho Is Kate Garraway New Partner? The Truth Revealed

-

Net Worth10 months ago

Net Worth10 months agoBrandi Raines Net Worth 2025: Age, Bio, Career, Husband and Children

-

Net Worth10 months ago

Net Worth10 months agoBetsy Grunch Net Worth 2025: Salary, Career, Husband, and Life Story

-

Biography9 months ago

Biography9 months agoSalma Shah Biography: Age, Career, Net Worth, Husband and Children