Tech

What Makes a Coil Winding Specialist Essential for Micro-Coil Applications?

Published

2 months agoon

By

IQnewswire

A coil winding specialist is someone or a team that makes coils carefully to exact demands. These are not ordinary coils off the shelf but coils built for specific machines, devices, or conditions.

In today’s world, many devices need coils that are tiny. Sometimes coils must be microscopic. Wires may be ultra‑fine. Spaces may be small. The manufacturing tolerances often are strict. In such cases, a regular coil maker, using standard methods, may not be enough.

A coil winding specialist has the skills, the tools, and the know-how to handle these hard jobs. They know how to work with very fine wire. They know how to wind coils tightly or precisely. And they understand how electrical, thermal, mechanical and spatial requirements affect coil design.

If you need coils for advanced sensors, medical equipment, micro‑motion devices, or compact electronics, a coil winding specialist can make the difference between a working product and a failure.

What Does a Coil Winding Specialist Do – Inside the Process

1. Understand exact technical requirements

Before winding a single wire, a good specialist spends time learning what is needed. They ask:

- What is the coil going to do? Inductance? Electromagnetic field? Signal?

- What is the space available? Is it very small, or oddly shaped?

- What is the wire type needed? Ultra-fine? Insulated? Special conductor?

- What are environmental demands? Temperature? Humidity? Vibration?

Only after these are clear, can the winding begin in a way that ensures correct performance.

2. Choose right materials and insulation

Many coils use copper or similar conductive wire. But when coils are tiny or must operate under special conditions, more specific materials or insulation are used.

The insulation must survive bending and tight winding. The conductor must give reliable electrical behavior. The specialist knows which material works best in which case.

3. Handle ultra-fine wire and micro-coils

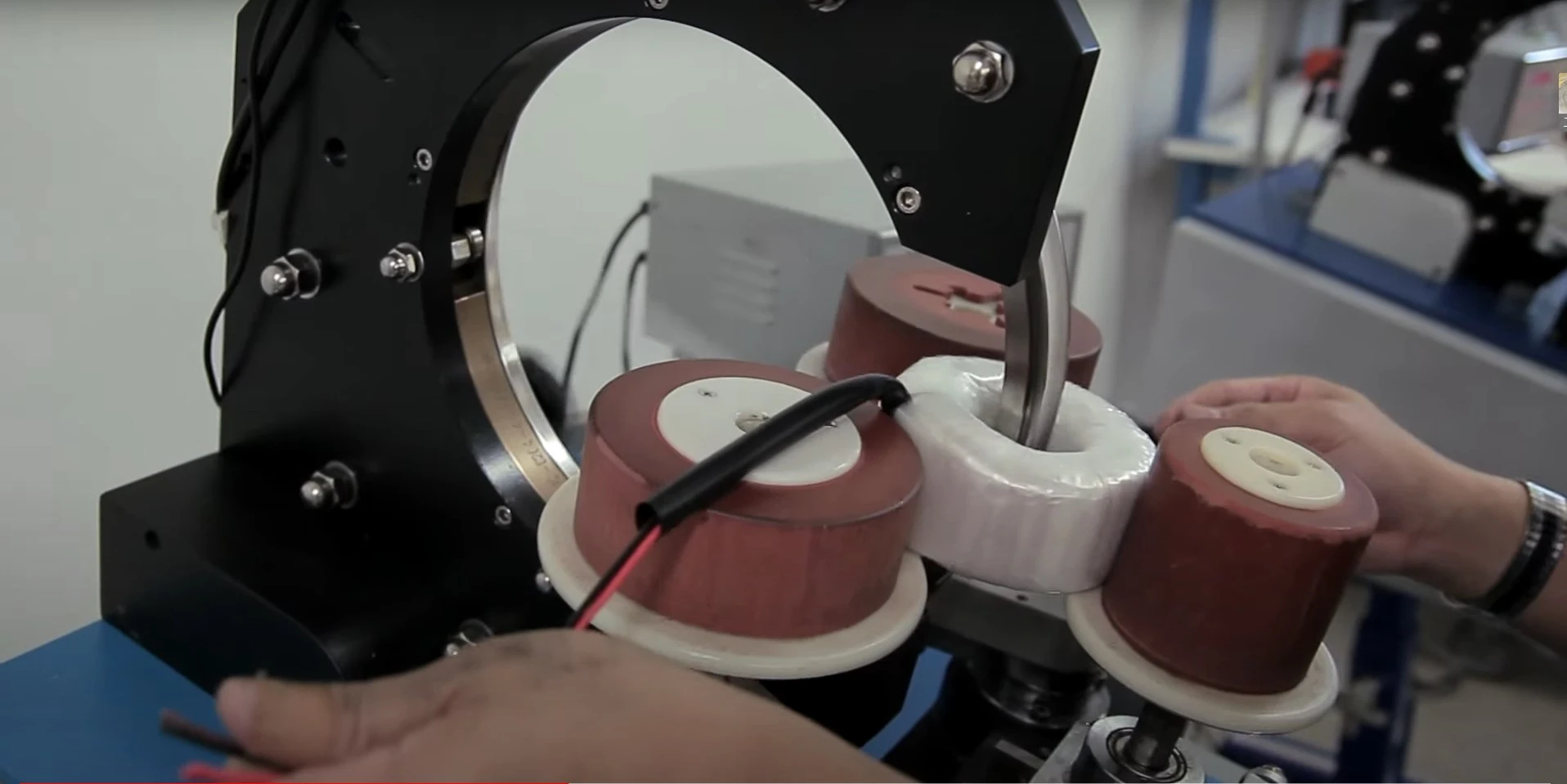

When the wire is extremely thin, or the coil must be small or tightly wound, normal methods don’t work. The specialist may need micro-winding machines, controlled tension systems, clean-room–like conditions, precise alignment.

This is delicate work. The specialist must avoid damaging insulation. They must ensure each winding is correct. Even tiny defects may cause the coil to fail.

4. Ensure precision, testing and quality control

After winding, coils often go through tests. Electrical measurement (resistance, inductance, insulation integrity). Possibly thermal or stress testing if coil will face heat or mechanical load. For sensitive devices, testing may include vibration, environmental conditions, long-term stability.

Quality control is essential. A coil winding specialist ensures each coil meets all requirements before it leaves the workshop.

When You Really Need a Coil Winding Specialist

You don’t always need a specialist. For many simple devices, a generic coil works fine. But in these conditions you should look for a specialist:

- Your device demands an unusual coil shape or size.

- You need ultra-fine wire, or a coil with small diameter or compact geometry.

- Your coil must meet strict tolerance levels (size, electrical tolerance, insulation).

- Your application is sensitive: medical devices, sensors, micro‑electronics, aerospace, high‑reliability systems.

- You expect high performance in demanding environments: temperature shifts, vibrations, long operational life.

In such cases, a coil winding specialist offers the precision, flexibility, and reliability you need.

What to Look For When Evaluating a Coil Winding Specialist

If you search for a coil winding specialist (or a vendor claiming to be one), check these factors carefully:

Technical understanding:

They should ask detailed questions about your needs. Not just: “How many coils do you need?” But: “What is the coil for? What environment will it face? What performance do you expect?”

Material flexibility:

They should handle different wire types, insulation types, maybe even exotic conductors; depending on application.

Precision winding capability:

The facility or team should have equipment (or methods) for tight winding, micro‑coils, ultra‑fine wires, or specialized shapes.

Quality control and testing: Insulation testing, electrical measurement, possibly environmental tests. They should show commitment to quality, not just quick volume winding.

Communication and clarity:

They must speak clearly about limitations, possible failures, timelines. A specialist who promises “everything at any size with no restrictions” — be cautious. Real expertise acknowledges challenges.

Scalability and production options:

If you need only a few prototypes — fine. If you need hundreds or thousands they should support volume production without losing quality.

Why Coil Winding Specialists Are Vital for Modern Technology

Modern technology moves fast. Devices become smaller. Tolerances get tighter. Demand goes up for reliability, efficiency, longevity.

Sensors shrink. Medical implants become more precise. Electronics get more compact. Robotics demands finer components. Renewable energy systems push coils to work under extreme load.

In all these cases, a standard coil won’t cut it. A specialist can deliver coils that meet all those constraints. That keeps devices safe, functional, efficient. That allows engineers to design boldly, without worrying about coil limitations.

In short: coil winding specialists enable innovation. They make possible what standard methods can’t.

Final Word

If your project involves ordinary coils for simple devices, a standard supplier may work. But if you face tight spaces, small sizes, fine wires, or strict performance and reliability needs, a coil winding specialist is the real choice.

They bring technical insight. They manage delicate materials. They ensure precision. They guarantee quality.

In a world pushing the limits of miniaturization and performance, having a reliable coil winding specialist can make or break your design.

FAQs:

Can they make a micro-coil that actually fits and works in my medical device?

Yes. Coil winding specialists analyze your exact device requirements, including size constraints, wire diameter, and electrical performance. They ensure each micro-coil fits perfectly and functions reliably, so your sensitive medical or precision equipment performs exactly as intended.

These wires and insulation are extremely delicate, what if they damage them?

Specialists handle ultra-fine wires and sensitive insulation with precision tools, controlled tension, and careful alignment. Each step is designed to prevent damage, giving you confidence that even microscopic coils remain intact and fully operational.

We need these coils fast, but quality and reliability can’t be compromised, can they deliver?

Yes. Experienced coil winding specialists balance speed with strict quality control, delivering prototypes or production batches on time without sacrificing performance, reliability, or compliance with industry standards.

S.O.S. vs block bottom paper bags: design differences

Unlock 20% Savings with Optimized Final Mile Routing

Benjy Rostrum’s 60 Minute “Reference Track Swap”: A Music Producer’s Team Activity That Turns Creative Chaos Into a Shared Vision

The 3 Best Image to Video Tools for Social Creators in 2026

The Content-Creator Angle: Using an AI Music Generator as a “Soundtrack Workflow,” Not a Toy

Cryptocurrency Reputation Management as a Growth Engine: How Strategic ORM Campaigns Protect and Scale Crypto Brands

Four Celebrities That You Might Not Know are Advocates of Medical Cannabis

Top Mother’s Day Flower Trends in Australia This Year

One & Two Bedroom Apartments Near Me in Renton, WA: Great Options for Every Lifestyle

Building a Repeatable Sound: How AI Music Agent Helps You Create Music Series, Not Just One-Off Tracks

Who Is Kate Garraway New Partner? The Truth Revealed

Brandi Raines Net Worth 2025: Age, Bio, Career, Husband and Children

Betsy Grunch Net Worth 2025: Salary, Career, Husband, and Life Story

Salma Shah Biography: Age, Career, Net Worth, Husband and Children

Nomia Iqbal Biography: Age, Husband, Career, Net Worth and BBC Journey

Kay Crewdson Biography: Age, Date Of Birth, Husband, Children, and Net Worth

Sophia Wenzler Biography: Age, Date of Birth, Husband, Career Story, and Net Worth

Ági Barsi’s Untold Story: Sister Of Judith Barsi And Her Battle With Cancer

Mike Danson Biography: Age, Net Worth, Wife, Children and Full Story

What Is eTarget Limited? The Truth Behind Those Mystery Parcels

S.O.S. vs block bottom paper bags: design differences

Unlock 20% Savings with Optimized Final Mile Routing

Benjy Rostrum’s 60 Minute “Reference Track Swap”: A Music Producer’s Team Activity That Turns Creative Chaos Into a Shared Vision

The 3 Best Image to Video Tools for Social Creators in 2026

The Content-Creator Angle: Using an AI Music Generator as a “Soundtrack Workflow,” Not a Toy

Cryptocurrency Reputation Management as a Growth Engine: How Strategic ORM Campaigns Protect and Scale Crypto Brands

Four Celebrities That You Might Not Know are Advocates of Medical Cannabis

Top Mother’s Day Flower Trends in Australia This Year

One & Two Bedroom Apartments Near Me in Renton, WA: Great Options for Every Lifestyle

Building a Repeatable Sound: How AI Music Agent Helps You Create Music Series, Not Just One-Off Tracks

Categories

Trending

-

News4 months ago

News4 months agoWho Is Kate Garraway New Partner? The Truth Revealed

-

Net Worth9 months ago

Net Worth9 months agoBrandi Raines Net Worth 2025: Age, Bio, Career, Husband and Children

-

Net Worth10 months ago

Net Worth10 months agoBetsy Grunch Net Worth 2025: Salary, Career, Husband, and Life Story

-

Biography9 months ago

Biography9 months agoSalma Shah Biography: Age, Career, Net Worth, Husband and Children